From Classic Baby Gym to Modern Play Tent

Lalo, a company founded by Greg and Michael to revolutionize the shopping experience for parents, approached Doris Dev to design, engineer, source, and manufacture a Play Gym for children.

The goal for the Lalo Play Gym project was to create a modern twist on the classic baby gym, one that could easily convert into a play tent as the child grows and be quickly disassembled for storage.

Services Rendered

Industrial Design

Engineering

Manufacturing

Freight

Lalo I Play Gym

ID Foundation

Challenges: Space, Assembly, & Obsolescence

After conducting research on the landscape of play gyms, we found that these products often require a considerable amount of space and can be challenging to assemble and disassemble. Additionally, many children's products are designed with a specific age

group in mind, leading to quick obsolescence as children grow older.

Design Development

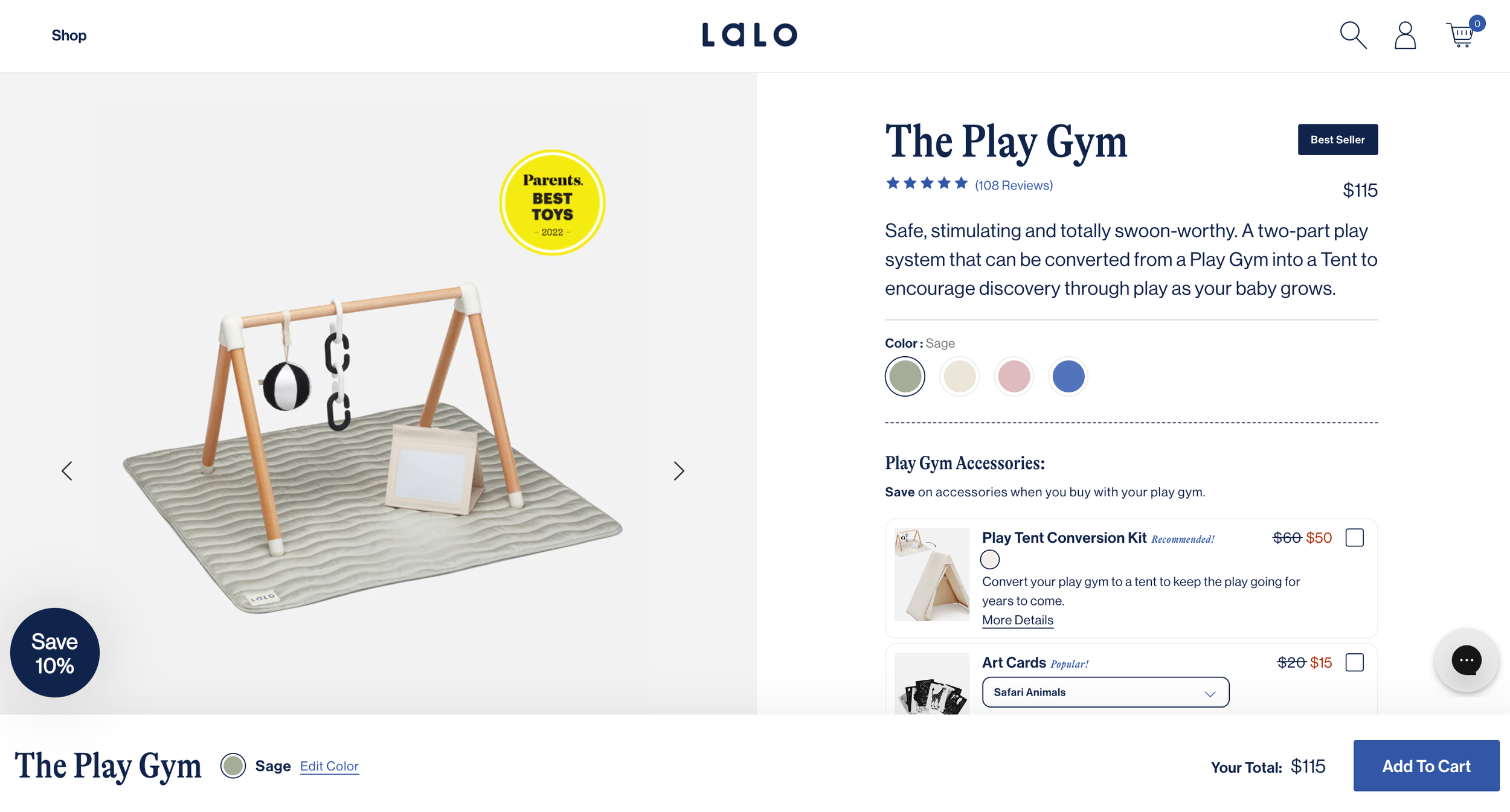

The Lalo Play Gym was designed to be a dynamic play-set for babies and toddlers. Babies lie on the soft play mat underneath the triangular beechwood structure while playing with the dangling Sensory Ball or Silicone Teether and observing themselves in the Mirror Prism. As babies grow, the Lalo Play Gym grows with them. The product offers an expansion set which converts the triangular structure into a tent frame covered with canvas, encouraging discovery through play as the child grows. Set-up and care is easy, featuring no-tool assembly, lightweight components, and machine-washable fabrics. This design makes it convenient for parents to break down and store the Play Gym, freeing up living space with ease.

Designing a Dynamic Play-set

Engineering

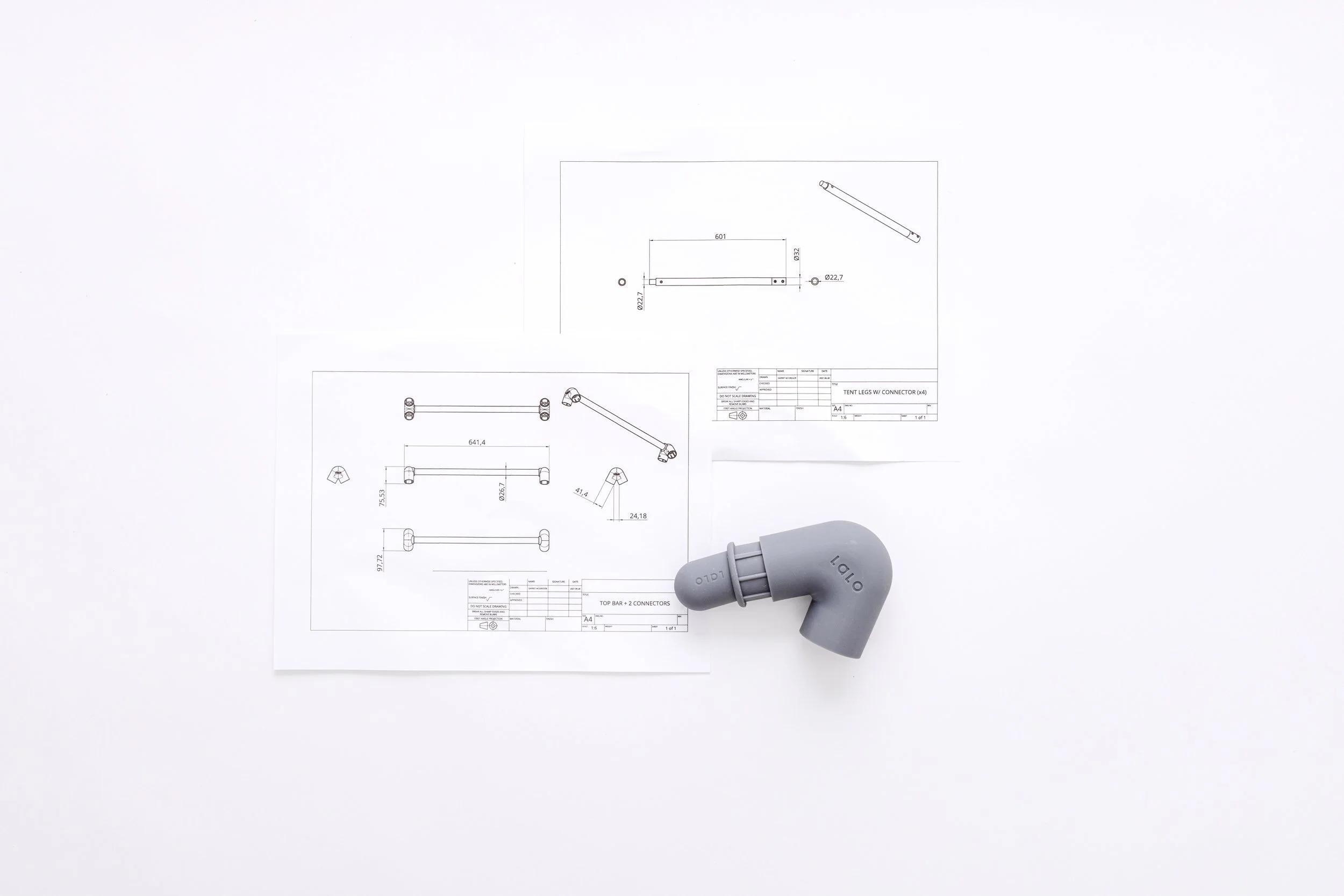

From CAD to Prototype

The Doris Dev Engineering Team was tasked with implementing the Play Gym design using iterative cycles of CAD Design and Prototype Fabrication. Several key engineering challenges were encountered, such as how to slightly loosen and fold the gym without compromising the structure or copying existing models. Ultimately, the team resolved this challenge by incorporating a connector that maintained the Play Gym's easy-to-disassemble snap feature. Additionally, they created internal rib structures in the connectors to accommodate the tolerance range of wood, and carefully dialed in the geometry to ensure a solid connection between the wood and plastic components.

Manufacturing

Key Challenges Conquered in the Making

Collaborating with a reliable supplier is critical to building a high-quality product. At Doris Dev, our sourcing team leveraged our extensive network to identify a supplier that was uniquely equipped to overcome the challenges of the Play Gym project. During the manufacturing process, our team overcame several obstacles to produce a superior product. One of the key challenges we faced was identifying the proper hardware to fasten the plastic connectors to the wood in a manner that could be repeatedly disassembled and reassembled without causing wear and tear to the wood threads. With the help of our experienced suppliers, we were able to identify the optimal hardware and manufacturing processes to achieve the desired result.

The Results

In January 2022, Lalo's Play Gym hit the market to the delight of parents and children. Its versatility was an instant hit, easily transforming from a baby gym to a play tent as the child grows. Customers appreciate this modern take on the classic product, which offers more functionality than traditional options.

“The lightweight, luxurious design, machine-washable fabric, and no-tool assembly make this modern Lalo Play Gym — which converts into a tent as baby grows — a no-fuss choice for first-time moms.”

Image credits: Lalo & Doris Dev

View Other Projects

Canopy

Loftie

Fable

Blueland