Reinventing Saintly's Dispenser: Scalable Design with Premium Features and Intuitive UI/UX

Doris Dev reimagined Saintly's V1 Dispenser design to upgrade features, enhance user experience, and support the product scalability. We reimagined the product to become the "Tesla of shitting," with a mass-production-friendly cartridge system, creamy shaving-cream-quality foam, and an intuitive dispensing UI/UX.

The design includes easy and durable installation, rechargeable batteries lasting four to five months, IP protection, and maintains the same size or smaller.

Services Rendered

Industrial Design

Engineering

Manufacturing

Packaging

Saintly | The Clean Butt Kit

Designing the Next-Generation Dispenser: Motion Activation, Rechargeable Battery, and Tool-Free Installation

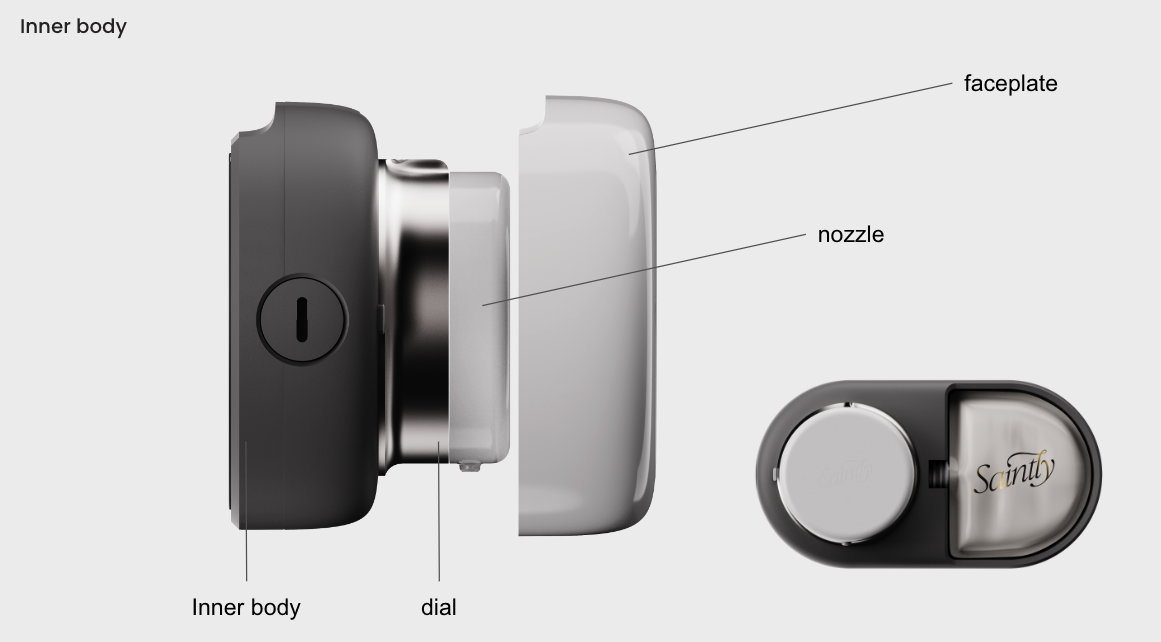

The new dispenser had several non-negotiable features to ensure functionality, usability, and aesthetics. In the industrial design phase, we ensured that a motion-activated dispenser operated with a rechargeable battery and would be easy to attach to a bathroom wall without tools.

The design allowed for freestanding use, featured unique interlocking components for IP protection, and an intuitive on/off button. Foam volume control, non-drip functionality, and a warming option were also essential, with a variant optimized for commercial use.

Industrial Design

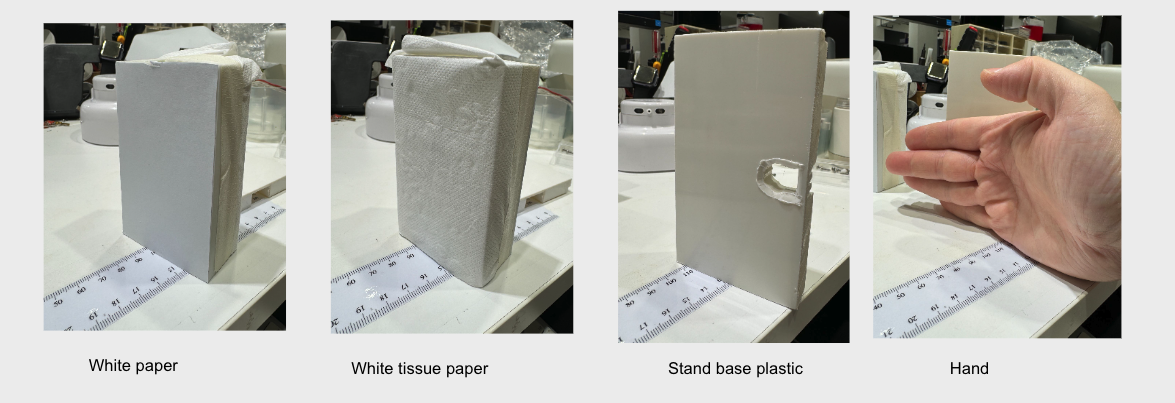

We conducted extensive testing to optimize the performance of the new Saintly dispenser, focusing on the sensor's triggering distance. The testing setup included varying IR LED pairs (5mm and 3mm) and different firmware settings (80mm, 90mm, 100mm, 110mm), with the understanding that distances above 110mm would necessitate hardware modifications. The tests were performed using different reflection media, including white paper, white tissue paper, a reflector made by the stand base, and a hand. These tests ensured that the dispenser would reliably activate under various conditions, contributing to its seamless user experience.

Engineering

Part 1: Sensor Testing for Seamless Activation

Engineering

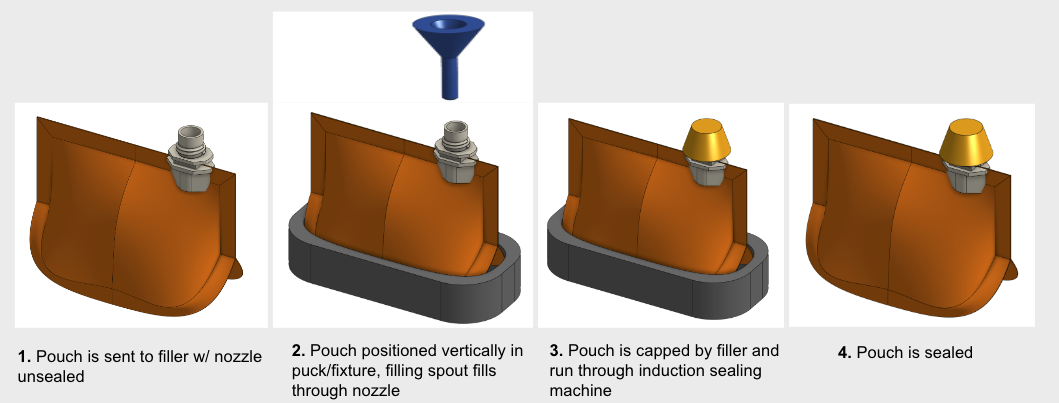

Part 2: Customizing a Proprietary Nozzle and Cap for Maximum Capacity and Functionality

The pouch engineering process was approached with customizations around the nozzle and cap design. We resolved issues with off-the-shelf components that didn’t allow for proper foil sealing and reduced the pouch's volume. By creating a custom nozzle and cap, Doris Dev maximized the pouch's capacity, ensured effective sealing, and made the pouches proprietary, preventing the use of incompatible products. This thorough approach maintained the integrity of the original design while optimizing functionality.

Manufacturing

Validating Practical Features for an Enhanced Laundry Routine

When tasked with sourcing the pouch for the dispenser, we took the following constraints to our sourcing partners to determine the best supplier. For example, the pouch needed to hold between 6 to 8 ounces of product, featuring a "penguin style" shape to be both functional and visually appealing, with a breakaway or puncture cap for easy dispensing.

We also made sure that the pouch was made from a combination of plastic and aluminum foil, providing durability and ensuring the product's freshness. Each order of these pouches needed to be produced in quantities of 10,000 pieces, making it a scalable solution for large-scale distribution and use.

Packaging

Developing and Designing the Packaging and Unpacking Experience

Doris designed a comprehensive packaging system that included a box and a custom pulp insert system to securely hold and organize the components. The shipper box was crafted from standard corrugate with a soft-touch finish, ensuring it arrived looking presentable even if shipped without an additional box or poly-mailer bag. A tamper-evident seal was incorporated for added security. While a kraft finish was initially considered for its durability and cost-effectiveness, it was ultimately decided that it wouldn't work with the soft-touch finish.

Interior Modularity

Our design allowed for a seamless and streamlined assembly and packing process across multiple locations. The box, which shipped from China, included a dispenser with a battery installed, faceplate attached, and wall bracket with pre-applied 3M strips, along with a charging cord, alcohol swab, and instruction brochure. At the USA 3PL, a cleanser pouch was added to each box, with additional SKUs—such as a base stand, refill pack box, and travel bottles—easily integrated into the package. The modular design ensured that the 3PL pick/packers could quickly add these items without disturbing the pre-packed contents, effectively accommodating the 25% of orders that included an extra refill cleanser pack.

Exterior Design

The outer box for Saintly was to function as both a mailer and shipper, which was achieved in the carefully vetted material and testing. We also designed the packaging to include a smooth, wet-pressed paper pulp tray to securely house the dispenser, with a modular design that can accommodate multiple SKU configurations.

The Results

The Saintly Butt Kit reimagines our bathroom hygiene.

“Saintly Stands Out in the Hygiene Industry with Its Heavenly Butt Kit”

Image credits: Saintly & Doris Dev

View Other Projects

Canopy

Loftie

Lalo

Blueland